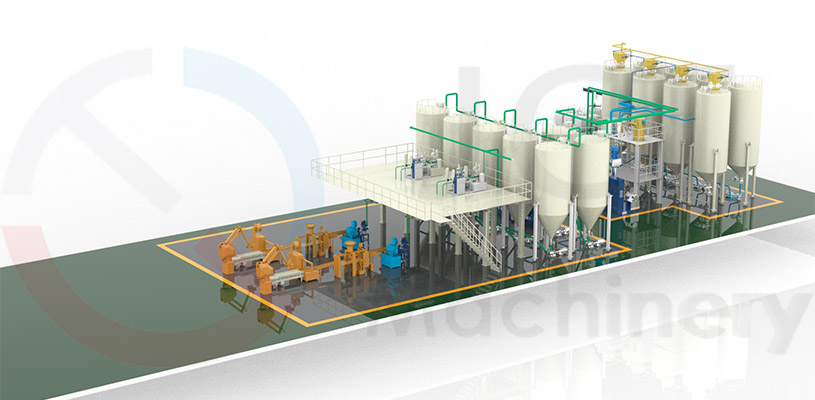

JCT provides one-stop heat resistant silicone sealant production line turnkey project, from formula design, equipment manufacturing, on-site installation and commissioning, personnel training to post-sales maintenance, to ensure that customers can quickly build factories and start production.

| Ingredient | Function |

| 107 glue | Base glue |

| Fumed silica (white carbon black) | Thickening, reinforcing, thixotropic agent |

| Platinum catalyst / dealcoholization crosslinking agent | Curing agent |

| Silane coupling agent | Improve bonding performance |

| Flame retardant / heat-resistant filler | Improve temperature resistance |

| Additives (auxiliary agents, anti-settling agents, etc.) | Modification and regulation |

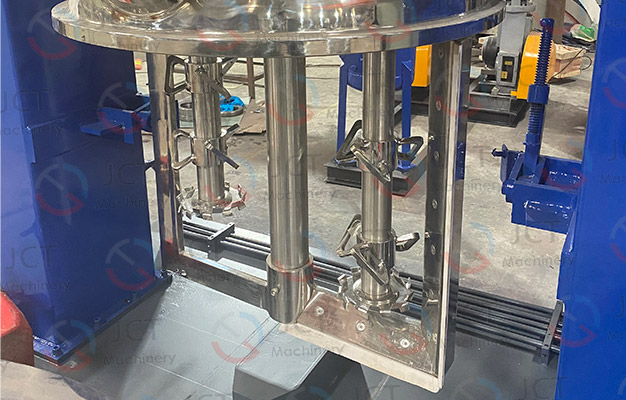

1. Strong ability to handle high-viscosity materials

Triple shaft mixer can stably handle high-viscosity silicone systems above 500,000cP, ensuring uniform mixing, no dead corners and no agglomeration.

2. Mixing and degassing under vacuum

Heat resistant silicone sealant production line is equipped with a high-efficiency vacuum system, which can be vacuumed during the entire process of mixing, dispersing and storing glue, effectively removing microbubbles and imrpoving product density and high-temperature sealing performance.

3. Precision temperature control system

Equipped with an electric heating jacket or thermal oil circulation system, it offers a wide temperature control range (room temperature to 200℃) with an accuracy of ±1℃, preventing silicone crosslinking and performance degradation due to temperature fluctuations.

4. Multi-stage dispersion design

Triple shaft mixer's high-speed dispersing discs + medium-speed butterfly blades + slow-spwwd "山"-shaped blade stirring system can effectively disperse high-temperature fillers to ensure uniform distribution of fillers.