JCT

JCT

Nov 04,2025

Nov 04,2025

As the chemical industry enters the "industry 4.0" era, adhesive production no longer relies solely on manual operation and experience-based control.

The main problems faced by past production lines included:

Nowadays, with the rapid development of digital technology, the Internet of Things (IoT), and artificial intelligence, adhesive production line is gradually moving towards a new stage of intelligent, information-based, and visualized management.

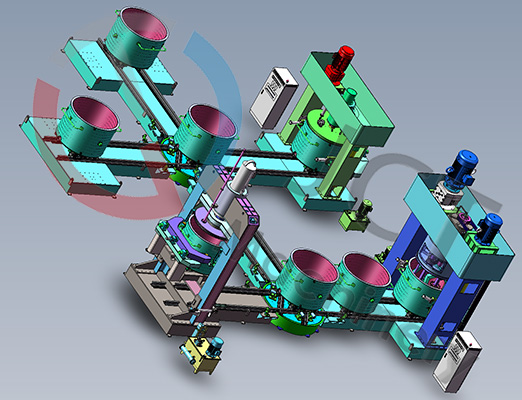

All major equipment (reactor, double planetary mixer, sigma mixer, triple shaft mixer, filling machine) can be centrally controlled via PLC.

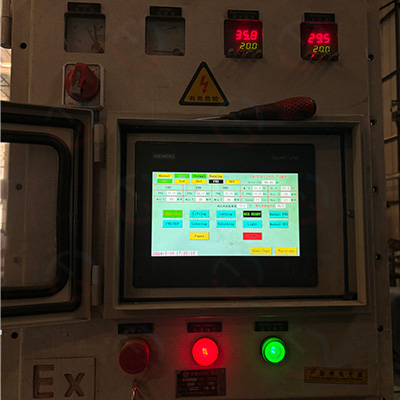

The touchscreen (HMI) displays process parameters such as stirring speed, temperature, pressure and vacuum in real time.

Data is automatically recorded, and alarms are automatically triggered for abnormalities, ensuring production stability.

It can be connected to a remote monitoring system, enabling remote viewing and control via mobile phone/computer.

Automatic batching and feeding are achieved through a robotic arm and weighing sensors.

The system automatically records the proportions of each component, reducing human error.

A metering pump system can be used for precise feeding of viscous liquids.

One-click recipe recall is possible-ensuring product consistency.

Real-time acquisition of data such as temperature, pressure, stirring speed and reaction time.

Automatic generation of production reports for easy quality tracking and process optimization.

Integration with ERP systems enables end-to-end management from order to production.

The cloud platform can monitor equipment operating status in real time.

The system automatically identifies abnormal signals (such as abnormal current or temperature control failure).

Engineers can remotely diagnose, adjust parameters, or guide customers in maintenance, reducing downtime.

The adhesive industry is undergoing a revolution from "experience-based manufacturing" to "intelligent manufacturing."

Future competition will no longer be merely a comparison of equipment performance, but a contest of the level of intelligence in production lines.

JCT will continue to drive digital upgrades, creating more efficient, safer, and more controllable adhesive production solutions for its customers.