Applications of Nail Free Glue

- Decoration and carpentry installation: Used for fixing wood moldings, skirting boards, decorative panels, drywall, door frames and glass.

- Home improvement diy: Furniture repair and fecorative pendant installation.

- Advertising: Quickly bond and fix billboards, light boxes, and other applications.

- Automotive and Marine: Interior trim and sealing.

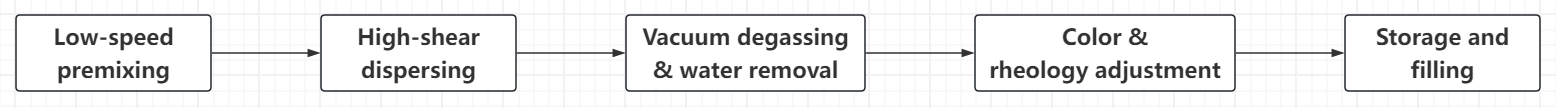

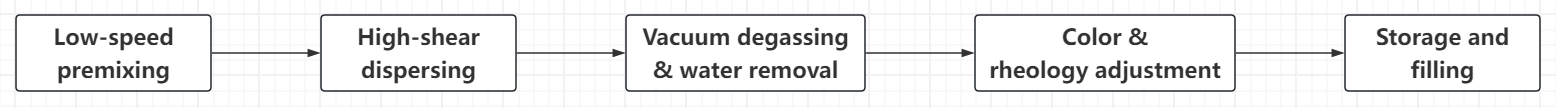

Nail Free Glue Production Process

Nail Free Glue Production Line Main Equipment : Reactor

- Structure: Vertical jacketed reactor with coaxial or dual-shaft agitation (anchor/frame type+high-speed dispersing disc, or anchor type+rotor/stator emulsifier), scraped wall.

- Material: SS304/316 for surfaces in contact with the medium. SS316 recommended for solvetnts; FKM/FFKM seals.

- Vacuum and nitrogen blanketing: Vacuum to -0.08 to -0.095MPa, nitrogen blanketing at the reactor top (dew point ≤ -40℃).

- Temperature control: Thermal oil or hot/cooling water jacket, controllable from 40-90℃; multiple temperature measurement points on the reactor wall and bottom.

- Powertrain: Variable frequency drive; low-speed impeller 10-60rpm, dispersing disc 300-1500rpm (adjusted with viscosity and batch size).

Why Choose Reactor?

- Multifunctional: Premixing, dispersiong, degassing, water removal and color adjustment are all performed in a single, enclosed space.

- Sealing advantage: Stable vacuum and nitrogen sealing are easier to achieve than conventional open dispersing tanks or planetary reactors.

- Scalability: Scalability from 200-500L pilot scale to 3-5 m³ mass production, with excellent parameter transferability.

JCT's Nail Free Glue Production Line Turnkey Project is your best choice!

- Vacuum reactor main technology

The closed mixing environment prevents moisture and air ingress, improving colloidal stability.

Dual-shaft or coaxial mixing structure efficiently disperses pigments and fillers while ensuring uniform mixing of medium- and high-viscosity systems.

A vacuum level of -0.095MPa significantly reduces air bubbles and improves bonding performance.

- Fully automatic dosing and precise metering

Powders are fed using vacuum to reduce dust contamination.

Online weighing of liquid raw materials allows for formulation accuracy within ±0.2%.

- Temperature control and safety design

A jacketed heating/cooling system maintains a temperature range of 40-90℃, ensuring stable reactions.

Solvent-based formulations are available with an optional fully explosion-proof design, compliant with ATEX and IECEx standards.

- Efficient filling and packaging

Compatible with 300mL rigid cans and 400-600mL sausage packs, it features automatic sealing, coding and weight rejection.

Filling accuracy of ±1%, saving raw materials and reducing production costs.

JCT provide a comprehensive, full-process delivery service, from process design and equipment manufacturing to installation and commissioning, and personnel training, ensuring rapid production and stable operation. With comprehensive after-sales support and spare parts supply, JCT ensure your nail free glue production line remains highly efficient.

Feel free to chat with us for the nail free glue production line turnkey project: +86-181 3837 3963 (Whatsapp, Wechat) or jctben@mixmachinery.com.

JCT

JCT

Aug 13,2025

Aug 13,2025