Get for free:

Technical consultation: +86-181 3837 3963 (Whatsapp, Wechat) or jctben@mixmachinery.com.

| Component | Raw material | Function |

| Base resin | Polyether PU prepolymer | Provide main body performance |

| Plasticizer | Diisononyl Phthalate | Adjust rheological properties |

| Filler | Nano-CaCO₃ (surface treated type) | Enhance/reduce costs |

| Thixotropic agent | Gas phase SiO₂ | Anti-sagging |

| Catalyst | Dibutyltin dilaurate | Control curing speed |

| UV absorber | Tinuvin 770 | Weather protection |

| Pigment/additive | Rutile TiO₂ (yellowing resistance) | Coloring/special functions |

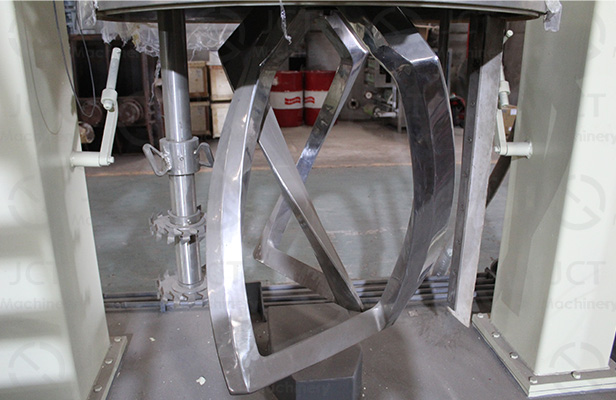

1. High-efficiency closed mixing system improves product consistency

Double planetary mixer can efficiently shear, flip and mix high-viscosity and high-filler systems. The whole closed design has no dead corners and the materials are mixed evenly, effectively preventing stratification or filler sedimentation.

2. Vacuum degassing+drying control to ensure reaction stability

The whole process is operated in vacuum to prevent water vapor from entering double planetary mixer and avoid prepolymer hydrolysis. The automatic drying system or nitrogen protection inhibits the cross-linking reaction caused by moisture and improves storage stability.

Effectively control product foaming, pinholes and other problems to improve the stability and aesthetics of the sealant.

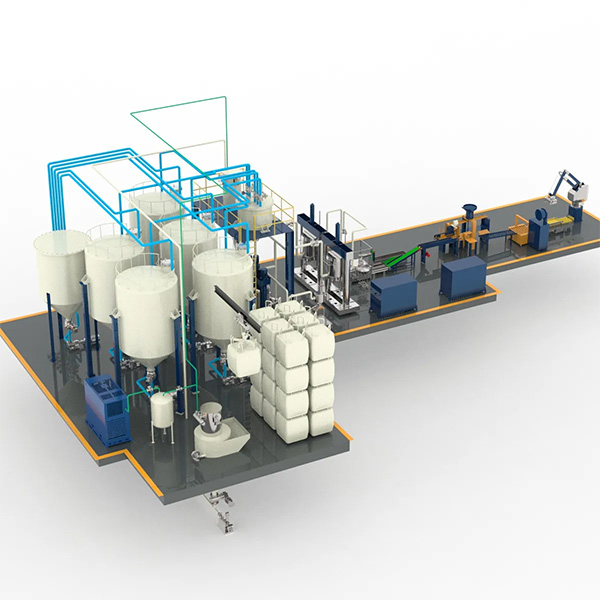

3. High degree of automation, reducing manual intervention

Polyurethane construction sealant production line can be equipped with automatic feeding, automatic batching, automatic weighing, automatic filling and automatic packaging system, supports formula memory and automatic switching.

Reduces manual operation errors, improves batch consistency, and facilitates large-scale continuous production.

4. Equipment material is corrosion-resistant and has a long service life

The parts in contact with the material are made of SS304/316. The movable material cylinder design is easy to clean, change color, and maintain.

It meets the needs of long-term use in corrosive environments containing isocyanates, plasticizers, etc.