Pillow hot melt glue packaging machine is mainly used to quantitatively fill molten hot melt glue and form it into pillow-shaped hot melt glue blocks. It is suitable for hot melt glue products with high requirements for weight accuracy, shape consistency and continuous production.

Suitable for large-scale production of small to medium-sized pillow hot melt glue products.

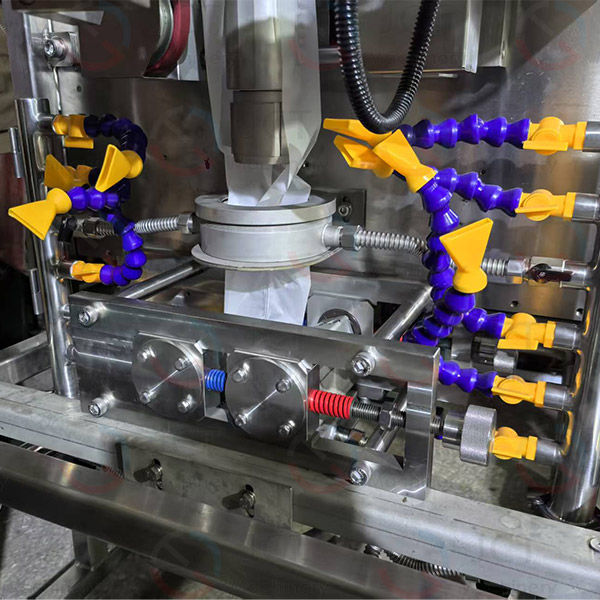

Melted hot melt glue is stably supplied by an insulated conveyor system and quantitatively filled into the molding cavity via a high-precision metering device. Under controlled conditions, it cools and solidifies, ultimately forming a uniform, pillow-shaped hot melt glue product.

The entire process is continuous and stable, ensuring that each product maintains consistent weight and shape.

1. Precise quantitative measurement

High-precision metering system

Stable filling weight

Effectively reduces product weight deviation

2. High molding consistency

Precision maching of pillow-shaped molds

Uniform and aesthetically pleasing finished product appearance

Beneficial for subsequent packaging and transportation

3. Stable temperature control

Independent temperature control for filling and molding areas

Prevents premature cooling or overheating of the colloid

Ensures stable colloid performance

4. Continuous production

Supports continuous filling and molding

Stable production capacity, suitable for large-scale production

Pillow hot melt glue packaging machine is typically used as the forming stage in hot melt glue production line. It works in conjunction with equipment such as reactor, sigma mixer, insulated tanks, and transfer pumps to achieve integrated production from melting to forming to packaging.