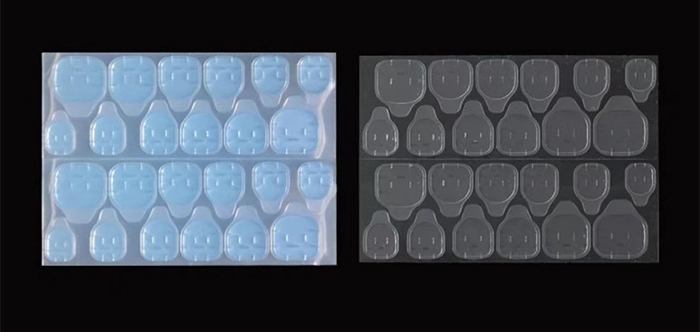

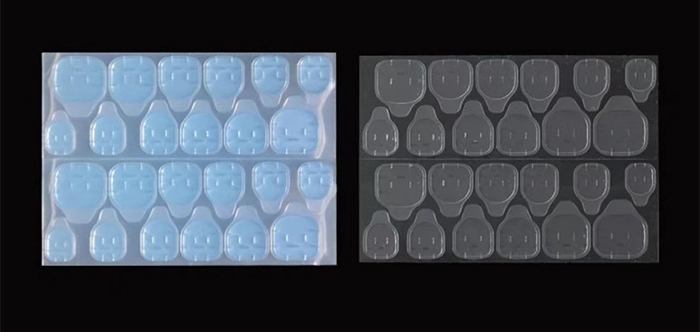

Nail jelly glue is an essential accessory for press-on nail.

Characteristics of Nail Jelly Glue

- High initial tack (sticks with light pressure)

- Peelable and won't damage the nail surface

- Soft and elastic, with a jelly-like texture

- Reusable application

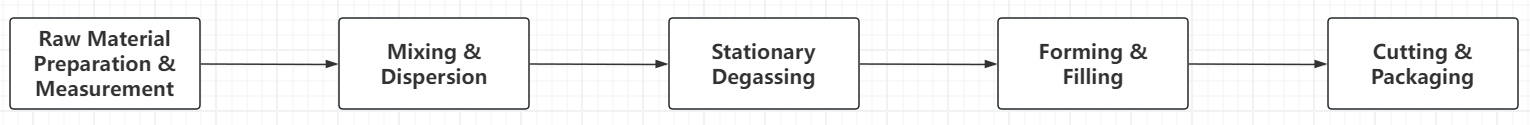

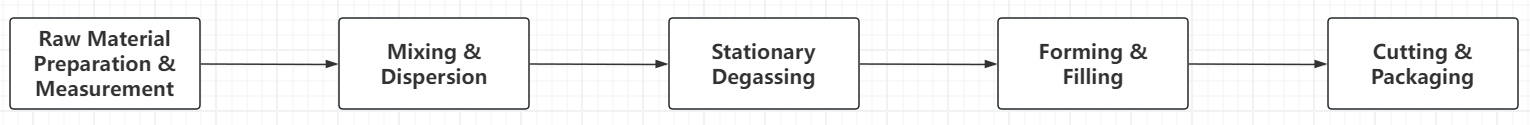

Nail Jelly Glue Production Process

Nail Jelly Glue Production Line Equipment Configuration

1. Sigma Mixer

- Suitable for high viscosity, gel-like, and elastic systems.

- Small gap between impeller and cylinder for more uniform mixing.

- Supports heating, cooling and vacuum degassing.

2. Heating and Temperature Control System

- Jacket heating (heat transfer oil / electric heating).

- Precise temperature control to prevent colloid aging or performance imbalance.

3. Vacuum Degassing System

- Effectively removes air bubbles generated during mixing.

- Improves the transparency and adhesion consistency of the nail jelly glue.

Technical Advantages of Nail Jelly Glue Production Line

- High mixing uniformity: Avoids localized areas that are too soft or too hard.

- Stable adhesion: Excellent batch consistency.

- Low bubble rate: Superior appearance and user experience.

- Customizable: Supports pilot testing, scale-up, and mass production.

A complete nail jelly glue production line is a combination of "chemical mixing equipment" and "precision coating and die-cutting equipment". The investment focus is on sigma mixer and the molding, filling, and slicing integrated line. For startups or small-scale production, investment can be phased in, first ensuring the quality of mixing and degassing, while the molding process can be semi-automated; while large-scale production can pursue fully automated assembly line operations.

If you are interested in nail jelly glue production line equipment, feel free to contact us: +86-18138373963 (Whatsapp, Wechat) or jctben@mixmachinery.com.