Putty paste usually uses water as a dispersion medium and belongs to water-based building materials. Strictly speaking, it is not a traditional "adhesive", but a certain proportion of adhesive powder or water-based latex is added as a binder to make the putty layer adhere firmly.

1. Raw material storage and conveying system

2. Feeding system

3. Ribbon mixer

Suitable for high-viscosity pastes such as putty paste and putty powder.

High mixing uniformity; can add cellulose ethers, latex, and additives.

4. Automated filling system

Screw-type automatic paste filling machine

Drum/bag packaging optional

5. Automated control system

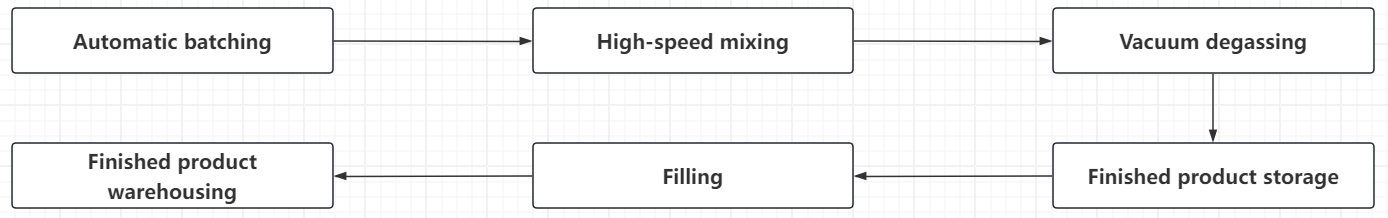

PLC automatic batching and mixing

Production line data recording and formula management

Automated packaging line (palletizing, lebeling)

There is semi-automatic putty paste production line can be optional, contact us for more informations: +86-18138373963 (Whatsapp, Wechat) or jctben@mixmachinery.com.

| Ingredient | Function |

| Talc/decalcium carbonate powder | Aggregate, filler |

| Cement/hydroxycarbonate | Provides hardness and strength |

| Latex/redispersible latex powder | Improves adhesion and flexibility |

| Cellulose ether | Retains water, prevents sagging, improves workability |

| Thickener | Adjusts consistency |

| Inhibitors, antifreeze | Improves weather resistance |

| Water | Dispersion medium |

| Note the following | Reason |

| Add ingredients precisely according to the formula ratio | Incorrect ratios will result in the finished product drying too slowly/too quiackly, easily becoming powdery, or becoming too hard |

| The order of ingredient addition must be correct (water→cellulose→fillers→additives) | Incorrect order will cause clumping, uneven dispersion, or viscosity fluctuations |

| Stirring speed and time must be fixed | Insufficient stirring easily leads to coarse particles; excessive stirring causes bubbles and abnormal viscosity |

| Use sealed mixing equipment to reduce dust | Avoid dust pollution in the workshop and protect worker health |

| A dust collection system must be added when feeding powder | Prevent the risk of dust explosion and improve environmental safety |

| The storage environment must be kept dry and protected from direct sunlight | High temperatures and humidity can cause putty to separate, mold or deteriorate |

| Storage tanks and pipelines should be cleaned regularly | To prevent residues from affecting the quality of new batches or introducing impurities |