Road Sealant Production Line Equipment Configuration

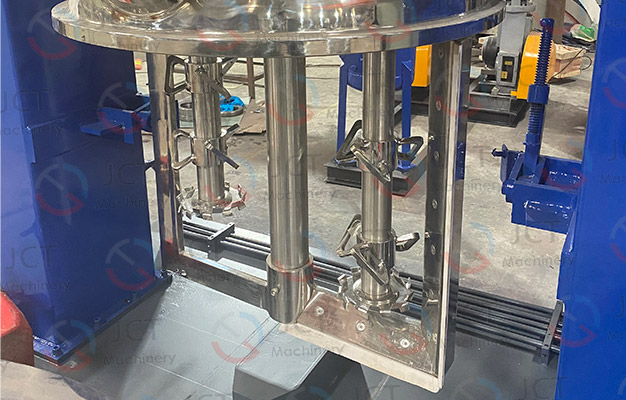

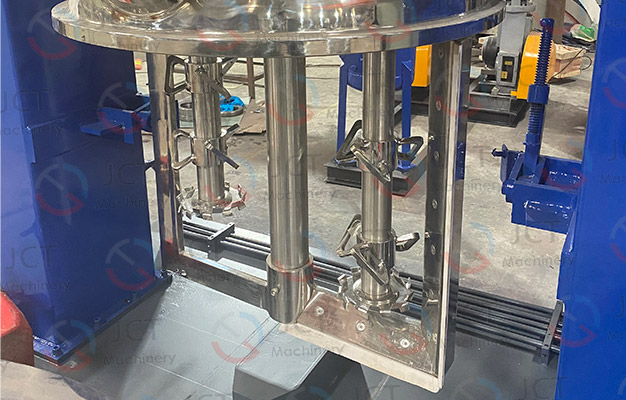

1. Triple shaft mixer

2. Thermal oil heating system

3. Vacuum system

4. Cooling and discharging system

5. Packaging machine

Road Sealant Production Process

- Heating and melting raw materials: Asphalt or resin raw materials must be heated and melted first.

- Premixing: Mix asphalt, polymer, filler and plasticizer in low-speed stirring.

- High-speed dispersion/shearing: Add additives and stabilizers, and use triple shaft mixer's dispersing disc and butterfly blades to evenly disperse.

- Vacuum degassing: Remove bubbles to ensure colloid density.

- Finished product cooling and discharging: Packaging through molds or automatic packaging machine (such as blocks, barrels or pillows).

Technical Feature of Road Sealant Production Line

- High temperature and wear-resistant design: The material of the agitator is high-strength stainless steel, which is wear-resistant and corrosion-resistant,

- High viscosity adaptability: Triple shaft mixer can handle materials of 100,00~1,000,000 cps.

- Intelligent temperature control: Adopting jacketed thermal oil heating system, the temperature control accuracy can reach ±1~2℃.

- Fully automatic production line optional: Automatic metering, PLC control, automatic packaging system.

Applicable products

- Modified asphalt road glue

- Polyurethane road glue (single component, two component)

- Epoxy road glue

- Road crack repair glue, expansion joint sealant