Two-component silicone sealant production line sharing a single mixing device refers to a system where both component A and component B of the two-component silicone sealant are prepared on the same high-viscosity mixing equipment through time-sharing production, thorough cleaning, and strict process control.

This solution significantly reduces equipment investment costs while ensuring stable product performance, making it particularly suitable for customers establishing new production lines, those with small to medium production capacities, or those who frequently switch between different formulations.

1. Feeding system

Equipped with a filter screen, it can effectively filter our impurities in the raw materials, improving product quality.

A weighing system can be installed to ensure precise ingredient dispensing according to the formula, guaranteeing product consistency.

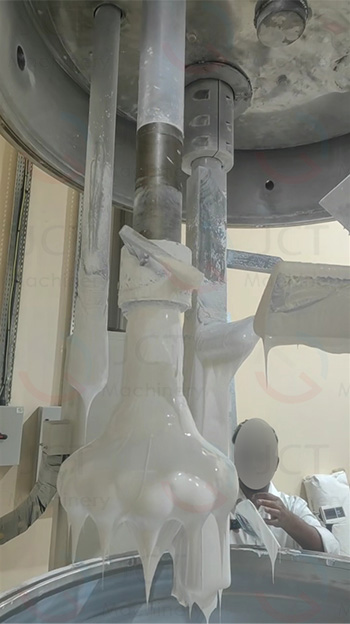

2. Double planetary mixer / triple shaft mixer

High torque, strong dispersion, suitable for high-filler systems.

3. Vacuum system

Vacuum mixing + degassing to improve product quality.

4. Cleaning and switching system

Online or offline cleaning design

Standardized cleaning procedures (SOP)

Cleaning status confirmation mechanism

5. Automation control system

Independent formula management for A/B components

Interlock logic to prevent misoperation

Hierarchical access control

The key lies not in the "number of devices", but in the process control capabilities:

Under mature processes and standardized operations, sharing equipment is a feasible and common solution in the industry.

Q: Will cross-contamination occur?

A: Time-sharing production + programmed cleaning + status confirmation, risk is controllable.

Q: Will product stability be affected?

A: Formula parameters are stored independently, and the process is repeatable.

Q: Can it be upgraded later?

A: Interfaces can be reserved for upgrading to a double A/B line system.