JCT

JCT

Nov 10,2025

Nov 10,2025

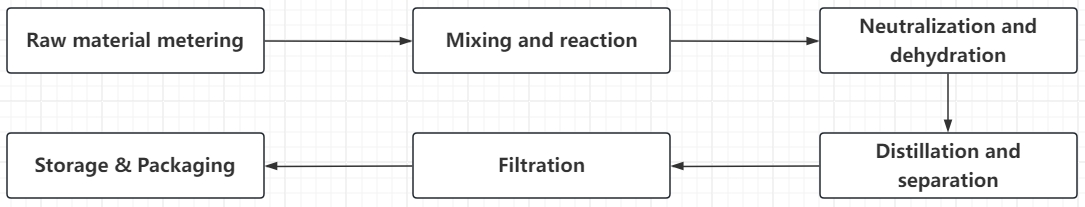

JCT provides a one-stop turnkey project for silicone oil production line, with equipment that meets the requirements for high-purity, automated and energy-efficient silicone oil production.

1. Reactor system

Material: stainless steel

Function: polymerization reaction, condensation reaction

Optional heating methods: thermal oil, electric heating, steam

2. Condensation and reflux system

Controls reaction temperature and recovers volatiles to ensure product purity.

3. Vacuum dehydration system

Removes moisture from the reaction, improving the transparency and stability of the silicone oil.

4. Distillation and separation unit

Utilizes a tower or thin-film evaporation system to achieve fractionation of silicone oil with different molecular weights.

5. Storage and filling system

Equipped with automatic metering and leak-proof devices to ensure safety and efficiency.

| Type | Product |

| Dimethyl silicone oil | Industrial lubricants, mold release agents, cosmetic base oils |

| Hydroxy silicone oil | RTV silicone rubber, defoamers, emulsifier raw materials |

| Vinyl silicone oil | Additive silicone rubber modifiers |

| Methyl hydrogen silicone oil | Waterproofing agents, fabric finishing agents |

If you are planning to establish silicone oil or organosilicon fluid production line, or a production system for RTV silicone, defoamers, or cosmetic silicone-based materials, welcome to contact us for customized solution: +86-18138373963 (Whatsapp, Wechat) or jctben@mixmachinery.com.