JCT

JCT

Nov 06,2025

Nov 06,2025

| Type | Definition |

| One-component adhesive | The adhesive contains all reactive components and does not require mixing, it cures directly upon use. Curing is typically triggered by air moisture, heat or light |

| Two-component adhesive | The adhesive consists of two components, A and B, which must be mixed in the correct proportions before use. Curing occurs through a chemical reaction between the two components |

| Comparison item | One-component Adhesive | Two-component adhesive |

| Composition and structure | Pre-mixed into a stable system, reacting only under external conditions | Component A (base agent) + component B (curing agent) are stored separately |

| Curing method | Relying on moisture, heat, light and air oxidation | The two components undergo a chemical reaction for cross-linking and curing |

| Curing speed | Relatively slow, dependent on external environment (temperature/humidity) | The curing speed is adjustable, typically faster and more thorough |

| Storage stability | Good, can be stored for a long time before opening | Separate storage provides good stability, but the mixture must be used immediately after mixing |

| Curing condition | Cures at room temperature or with heat | It usually cures via a chemical reaction at room temperature |

One-component adhesive is known for its ease of use and is suitable for small to medium batch production and light industrial applications.

Two-component adhesive, on the other hand, offer advantages in high strength, durability, and structural bonding, making them the mainstream choice in modern industrial manufacturing.

One-component silicone sealant: triple shaft mixer

Two-component silicone sealant: triple shaft mixer+static mixer

One-component PU glue: double planetary mixer+vacuum degassing system

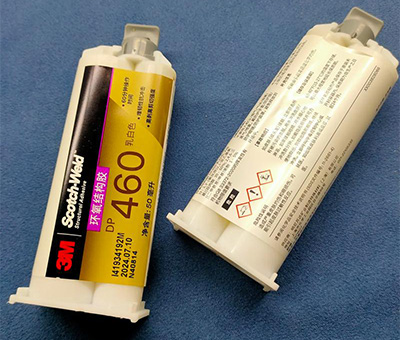

Two-component epoxy adhesive: two-component mixing system+precision metering pump