JCT

JCT

Sep 29,2025

Sep 29,2025

1. Acidic silicone sealant

Releases acetic acid (with a pungent odor) during curing.

Composed primarily of an acetic acid crosslinker (such as methyltriacetoxysilane).

Suitable for bonding glass and some metal surfaces, but may be corrosive to materials like concrete and marble.

2. Neutral silicone sealant

Releases alcohols or ketoximes during curing and has no strong odor.

Composed primarily of an alcohol or oxime crosslinker (such as methyltributyketoximesilane).

Provides better adhesion to a variety of substrates (glass, metal, stone, plastic, etc.) and offers superior weather resistance compared to acidic silicone sealant.

1. Acidic silicone sealant production line

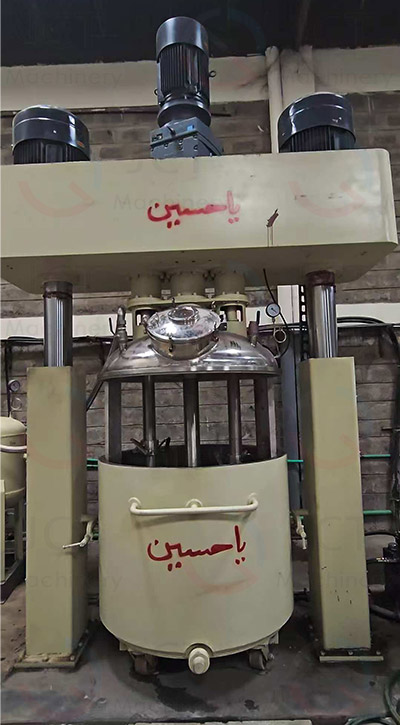

Triple shaft mixer + vacuum system + filler

Low investment cost, simple process.

2. Neutral silicone sealant production line

Triple shaft mixer + high-sealing vacuum system + automatic dosing + filler

Higher investment cost, but greater product added value and market demand.

| Acidix Silicone Sealant Production Line | Neutral Silicone Sealant Production Line | |

| Main raw material | 107 glue, fumed silica, acetic acid crosslinker | 107 glue, fumed silica, oxime or alcohol crosslinker |

| Mixing difficulty | Low-cost, stable reaction system | Higher, oxime crosslinkers are sensitive to humidity and impurities |

| Equipment requirement | Triple shaft mixer | Requires a more stringent seal and vacuum system to prevent moisture ingress |

| Vacuum system | Standard vacuum degassing | High vacuum (≤-0.098MPa) ensures colloid transparency and stability |

| Safety and environmental protection | Emits acetic acid odor during curing, exhaust gas emission device required | No strong acid odor, but sensitive to ambient humidity, requiring a stable production environment |

| Product application | Common architectural glass, interior decoration | Architectural curtain walls, stone, marble, metal, automotive and electronic appliances |

For entry-level investment: JCT recommend acidic silicone sealant production line, which requires minimal equipment investment and is relatively simple to operate.

For the high-end market: JCT recommend neutral silicone sealant production line, which offers superior weather resistance, a wider range of applications, and higher added value.

If you are interested our silicone sealant production line turnkey project, chat with us for more informations:

Phone: +86-181 3837 3963 (Whatsapp, Wechat)

Email: jctben@mixmachinery.com