What is hot melt glue?

Hot melt glue is a solid adhesive that can be applied after being heated and melted, and quickly solidifies and produces adhesive strength after cooling.

Main Ingredients of Hot Melt Glue

- Base resins: Such as EVA (ethylene-vinyl acetate copolymer), PO (polyolefin), PA (polyamide), SBS/SEBS (styrene-based thermoplastic elastomer), etc.

- Tackifying resins: Improve adhesion to the substrate.

- Wax: Adjusts softening point, flowability and cure speed.

- Antioxidants/Stabilizers: Prevent degradation during high-temperature processing.

Application Areas of Hot Melt Glue

1. Packaging industry

- Carton sealing, box bonding and courier bag gluing

- Food, beverage and pharmaceutical packaging

Advantages: Fast bonding, high strength and low-temperature resistance.

2. Bood and print binding

- Perfect binding, magazine, notebook and photo album binding

Advantages: Even bonding, fold resistance and beautiful finished product.

3. Furniture and woodworking

- Bonding wood boards, veneers, edge banding and composite panels

- Bonding sofas, mattresses and sponges to non-woven fabrics

Advantages: Environmentally friendly, non-toxic and durable.

4. Health care and medical

- Non-woven fabric lamination for diapers, sanitary napkins, masks, etc.

- Medical dressings, breathable tapes

Advantages: Soft, non-toxic and breathable.

5. Automotive and transportation

- Bonding automotive interior parts (ceilings, carpets, door panels, etc.)

- Automotive lighting and wiring harness mounting

Advantages: High-temperature and vibration resistance, long-lasting bonding.

6. Elestronics and electrical industry

- Wire fastening, component bonding and insulation

- Assembly of mobile phones, computers and other devices

Advantages: Fast curing, corrosion-free and excellent insulation.

7. Footwear and textiles

- Shaping and bonding of soles, insoles and uppers

- Heat sealing of clothing, non-woven fabric lamination

Advantages: Abrasion resistance and high flexibility.

8. Construction and decoration

- Flooring and wallpaper adhesive

- Lamination of thermal insulation and soundproofing materials

Advantages: Weather resistance and strong bonding.

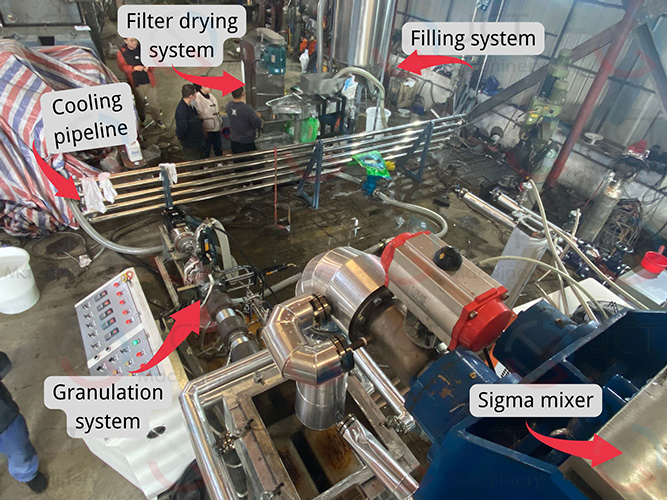

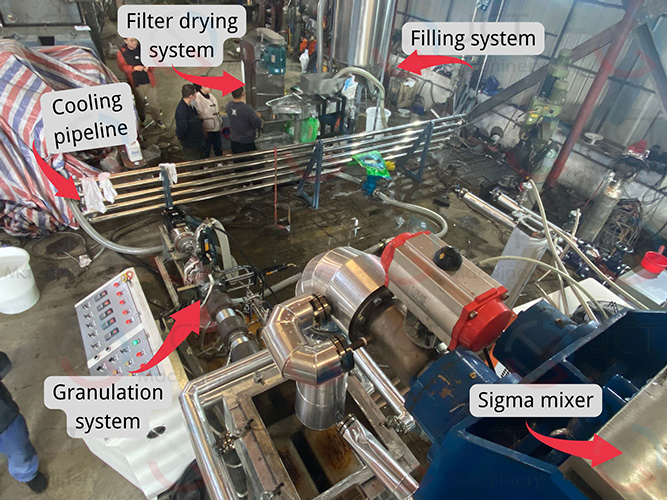

Reactor or Sigma Mixer for Hot Melt Glue Production Line?

Reactor (jacketed/coil)

- Strengths: Wide temperature control window (steam/thermal oil), vacuum/condensation reflux, precise metering and excellent batch reproducibility, and easy linkage with a gear pump and extrusion pelletizing for scalability.

- Applications: Chemical reactions (such as PUR propolymerization and PA polycondensation), medium- to low-viscosity systems, solvent/byproduct removal requirements, and continuous discharge and pellet/pillow packaging.

- Key feautres: Thermal oil system, vacuum and condensation, nitrogen blanketing (PUR, etc.), in-line filtration, weighing/metering pumps and torque/temperature/level monitoring.

Sigma Mixer (∑-shaped blades, with vacuum system)

- Strengths: High-torque mixing and dispersing for ultra-high-viscosity and highly filled systems, minimal dead zones, strong material circulation and clean discharge (hydraulic tilting/extrusion).

- Applications: SIS/SBS pressure-sensitive adhesive, high-viscosity EVA modification, high filling, small-scale pilot/multi-formulation plants.

- Key features: Double ∑-shaped blades high-torque motors, jacket heating/cooling, vacuum and degassing, nitrogen blanketing (when required), hydraulic tilting/screw extrusion and wear-resistant parts.

For continuous, scalable reactions → Reactor

For extremely high viscosity, heavy fillers and frequent line changes → Sigma mixer

For high demand for mixing and multiple production lines, consider using a tandem or split-function system: Reactor for pre-melting and metering, and sigma mixer for high-viscosity final mixing and discharging.

JCT can provide different types of hot melt glue production line turnkey projects, including full set of equipment, glue formula and free upgrade, installation and commissioning, after-sale services, help you one-stop establishing the production line.

JCT

JCT

Aug 20,2025

Aug 20,2025