JCT

JCT

Aug 28,2025

Aug 28,2025

Static mixer is highly efficient mixing device with no moving parts. In addition to its widespread use in the petroleum refining and chemical industries, it is also widely used in the pharmaceutical, food, mining, plastic extrusion and environmental protection sectors.

Compared to traditional mixing equipment such as agitators, colloid mills, homogenizers and venturis, static mixer offers advantages such as a simple process, compact structure, low energy consumption, low investment, high operational flexibility, zero maintenance, and excellent mixing performance. Static mixer can replace traditional equipment in all processes involving liquid-liquid, liquid-gas, liquid-solid and gas-gas mixing, emulsification, neutralization, absorption, extraction, reaction and heat transfer enhancement.

Static mixer is used in pipelines and produce a minimal pressure drop. When the system pressure in which a static mixer is used is relatively high, the pressure drop caused by the static mixer can be ignored. However, if the system pressure in which a static mixer is used is relatively low, the pressure drop of the static mixer must be verified. The method for calculating the pressure drop of a static mixer varies depending on the mixer model. For more information, please contact our technical department: +86-181 3837 3963 (whatsapp, wechat) or jctben@mixmachinery.com.

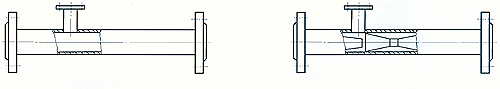

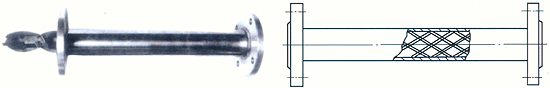

The SV unit is a cylindrical structure assembled from corrugated plates of a specific specification. Its maximum dispersion range is 1-2μm and the liquid-liquid and gas-gas phase inhomogeneity coefficients are: α √x ≤ 1-5%.

Typical Applications: gasoline, diesel, oil blending, brine neutralization, acid neutralization, gas mixing.

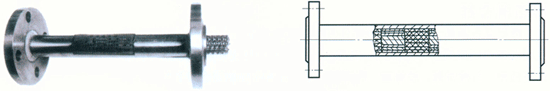

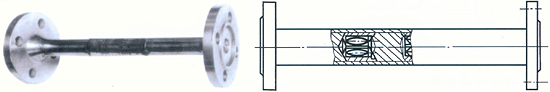

The SK unit is constructed by welding together single-channel, left- and right-twisted spiral blades. The maximum dispersion is ≤10μm, and the liquid-liquid and liquid-solid phase inhomogeneity coefficients are α √x ≤ 1-5%.

Typical Applications: chemical, petroleum, pharmaceutical, food, fine chemical, plastics and environmental protection, synthetic fibers, injection molding, color matching, papermaking, pulp and chlorine mixing, solvent deasphalting, acid-base neutralization, asphalt and oil blending, industrial naphthalene dephenolization, liquid hydrocarbon sweetening, polymer material mixing, color matching and heat transfer.

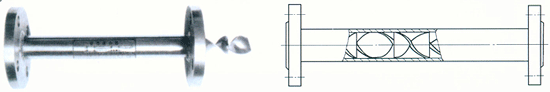

The SX unit is composed of intersecting horizontal bars arranged in a regular pattern to form numerous X-shaped units. SX static mixer's technical performance: liquid-liquid and liquid-solid phase inhomogeneity is α √x ≤ 1-5%.

Typical Applications: polymer blending, light ketone-benzene dewaxed oil, pulp chlorination bleaching, crude oil alkali injection process.

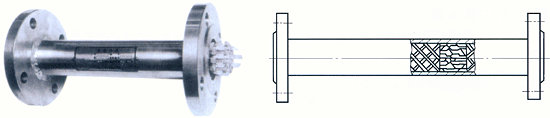

The SL unit is composed of numerous L-shaped units arranged in a regular pattern of intersecting horizontal bars. SL static mixer's technical performance is: liquid-liquid and liquid-solid phase inhomogeneity is ≤5%.

Typical Applications: wastewater treatment, polymer mixing, heat transfer, reaction, heat exchanger.

The SH unit consists of a dual channel with spiral vanes placed within the channel. The channels of adjacent units are offset 90 degrees. Afluid distribution chamber is located between the units. The maximum dispersion is 1-2μm, with a liquid-liquid and liquid-solid phase inhomogeneity of α √x ≤ 1-5%.

Typical Applications: acrylamide mixing, polymer material mixing, color matching and heat transfer.

Static mixer should be installed as close as possible to the initial mixing point of two or more streams. Its installation methods vary in different applications.

During fluid conveying, the mixing ratio is often affected by pressure imbalances between the various fluid streams. To better support users in utilizing static mixer, JCT has developed the SN distributor, which features the performance of a jet booster pump, ensuring the desired outlet pressure while maintaining the secondary flow rate. SN distributor consists of a nozzle, a receiving chamber, a mixing chamber and a diffusion chamber. The primary fluid passes through the nozzle, where its high velocity creates a low pressure at the conical inlet. This draws the secondary fluid into the receiving chamber, accelerating it. It then swirls within the mixing chamber and is ejected from the diffusion chamber at a constant velocity, ensuring smooth fluid delivery to the static mixer for mixing, achieving optimal results.

Application: suitable for feeding two or more fluids. When the pressures of the primary and secondary streams are unbalanced, a venturi distributor is used. Whe the pressures of the primary and secondary streams are balanced, a conventional distributor is used.