JCT

JCT

Jan 21,2025

Jan 21,2025

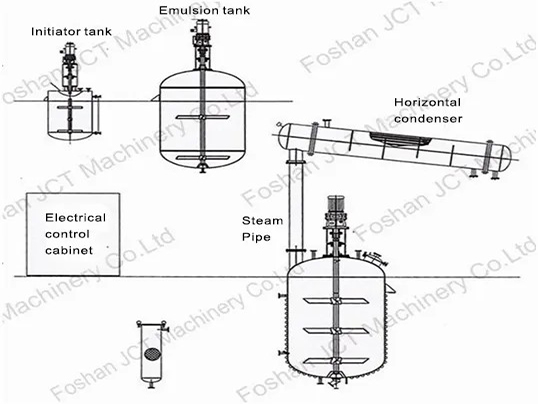

One of the most important equipment in white glue (PVA glue) production line is s reactor equipped with horizontal condenser.

1. Temperature Control and Stability Guarantee

The dissolution of PVA resin requires a higher temperature and the temperature in reactor must be kept stable to avoid excessive temperature causing resin degradation or too fast reaction. The horizontal condenser recovers the heat generated during the reaction through an external cooling system to ensure that the temperature remains within the ideal range and avoid overheating.

2. Prevent Material Volatilization and Solvent Recovery

During the production process, some solvents may evaporate. In the reactor with horizontal condenser, the evaporated material is condensed and refluxed into the reactor, avoiding material waste and facilitating solvent recovery, This not only saved production costs, but also reduces solvent emissions, and is more in line with environmental protaction requirements.

3. Improve Reaction Efficiency

The condenser avoids excessive evaporation of materials by continuosly recovering and cooling steam, ensuring that the material concentration in the reactor is always in a constant state. This can reduce material loss, improve production efficiency, and ensure the efficiency and stability of the production process.

4. Ensure Product Quality

During the production process of white glue, if the temperature control is unstable or the solvent evaporates too much, the viscosity of the final product may be unstable or impurities may appear. The use of horizontal condensers helps control the temperature fluctuationsin the reaction process, ensuring the stability of the quality of the final glue and meeting the requirementsof adhesion, transparency, etc.

5. Energy Saving and Consumption Reduction

By recycling steam heat through condensers for heating, the energy consumption of the external heating system of the reactor can be reduced and the energy utilization efficiency can be improved. This can significantly reduce the production cost for white glue production line with long-term continuous production.

6. Reduce Pollution and Emissions

Reactor with horizontal condenser can effectively reduce the volatile emissions of harmful gases and solvents, comply with environmental protection regulations, and reduce safety risks to operators.

1. High Degree of Automation

White glue production line is usually equipped with automated control systems, which can achieve precise control of parameters such as temperature, stirring speed, additive ratio, etc., and improve production efficiency and product consistency.

2. High Production Efficiency

Due to the automated control of each link, the production line can produce quickly and continuously, shortening the production cycle.

3. High Product Quality

Strict process control and quality inspection ensure the stability and consistency of white glue, meeting the use requirements of different fields.

4. Strong Environmental Protection

White glue is a water-based glue, does not contain toxic solvents, adn the production process is environmentally friendly, in line with modern green production standards.

5. Strong Adaptability

Production line can flexibly adjust the production formula and production scale according to market demand to meet the production requirements of different types of white glue.